Pressed powder is a staple in makeup routines, offering a convenient way to set foundation, reduce shine, and create a smooth finish. The packaging that holds this product, a Pressed Powder Case, is just as important as the cosmetic itself. A well-designed case ensures the powder stays protected, is easy to carry, and provides a pleasant user experience.

What Is a Pressed Powder Case?

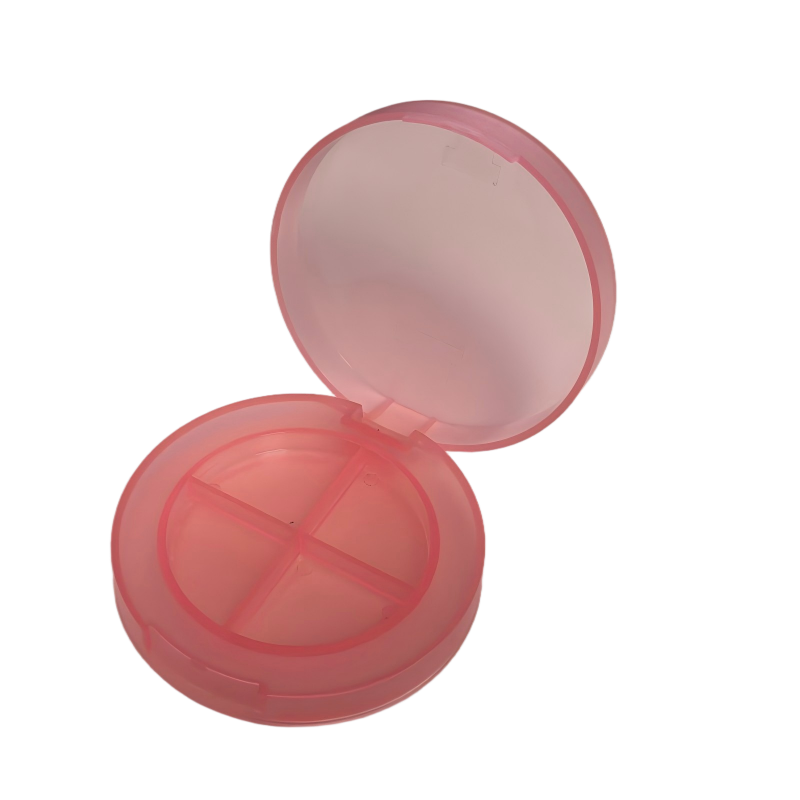

A Pressed Powder Case is a compact container designed to hold pressed powder securely. These cases are commonly made from plastic, metal, or a combination of materials to ensure durability while remaining lightweight. Most cases include features such as a mirror, a detachable puff, or a hinged lid that clicks shut to prevent accidental spills.

The design of the case affects usability, protection, and even the perception of the cosmetic brand. Cases that are sturdy and visually appealing enhance the user's confidence in both the product and the brand.

Material Selection and Construction

Material choice is key in manufacturing a Pressed Powder Case. Durable plastics such as ABS or polypropylene are often used because they resist cracking while keeping production costs reasonable. Some higher-end cases incorporate metals or layered finishes for a more premium feel.

Inside the case, the powder pan must fit securely to prevent movement. The lid and hinge mechanisms are tested for repeated opening and closing, ensuring the case remains functional over time. Factories producing Pressed Powder Cases often conduct stress tests to ensure the container maintains integrity during shipping and daily use.

Design Considerations for Users

User convenience is central to Pressed Powder Case design. Compact size, lightweight structure, and easy-to-use closures allow the case to be carried in a handbag or travel kit. Some cases feature refillable pans, which add sustainability and cost-efficiency for users who want to replace the powder without buying a new case.

Visual appeal is also important. Shape, color, finish, and branding details all contribute to the cosmetic's marketability. A case that looks attractive on a vanity or shelf can influence a customer's purchase decision.

Manufacturing Workflow

The production of a Pressed Powder Case involves several stages:

- Injection molding or stamping to create the main body

- Assembly of hinges, mirrors, and puffs

- Finishing touches such as polishing, painting, or adding brand logos

- Final quality inspection

Each step ensures the case functions properly and looks appealing. Consistent quality control prevents defects such as cracked lids, uneven finishes, or loose mirrors.

Quality Control and Testing

Quality control is critical in a Pressed Powder Case. Factories typically check for:

- Lid closure and hinge strength

- Powder pan stability

- Surface finish and color consistency

- Fit and comfort of the included puff

These checks help maintain consistent user experience and prevent customer complaints. Regular inspections also allow factories to adjust processes when minor defects are detected.

Customization and Branding

Many cosmetic brands request custom Pressed Powder Cases to match their style and market positioning. Manufacturers can adjust size, shape, color, and additional features such as built-in mirrors or magnetic closures. Customization allows brands to differentiate their products while keeping production manageable.

A Pressed Powder Case is more than just a container—it protects the powder, improves usability, and reinforces brand identity. From material selection and structural design to final assembly and quality control, each step in production ensures the case meets both practical and aesthetic standards. Understanding these processes helps buyers and cosmetic brands make informed decisions about packaging that complements the product inside.

English

English  中文简体

中文简体  عربى

عربى  Español

Español