Pressed powder cases are essential for packaging cosmetic products, offering both protection and a convenient way for consumers to apply makeup. Customizing these cases provides brands with the opportunity to create packaging that aligns with their vision and stands out in the market. There are several customization options available for pressed powder cases that cater to different brand identities and product requirements.

Material Selection

One of the main customization options for pressed powder cases is the choice of material. The material affects both the durability and aesthetic appeal of the case. Common materials include:

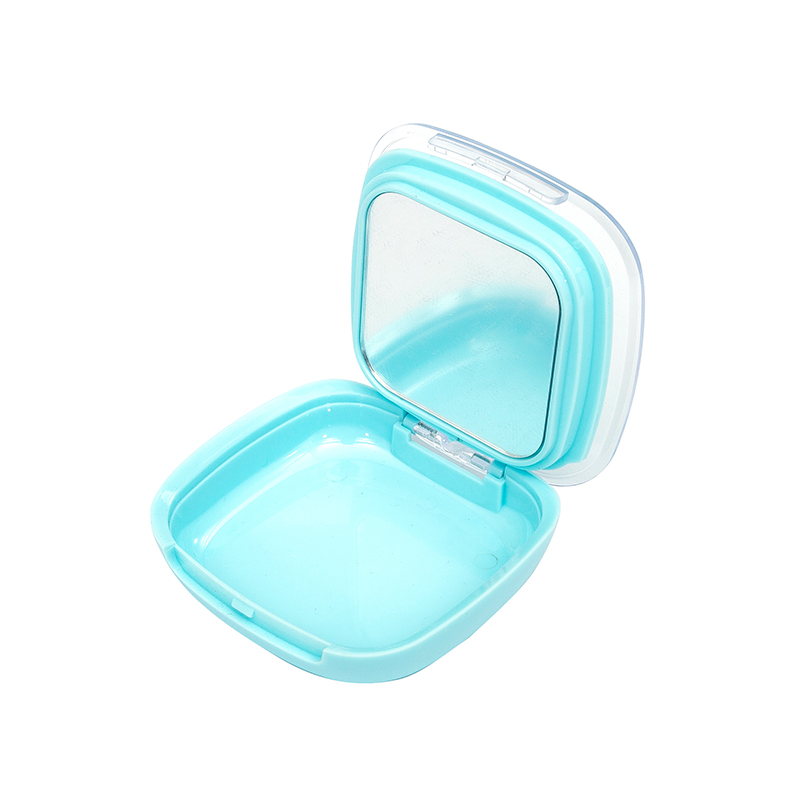

Plastic: Lightweight and cost-effective, plastic pressed powder cases are ideal for mass-market products. They can be easily molded into various shapes and are available in a range of colors.

Acrylic: Acrylic is a popular choice for higher-end packaging. It provides a more transparent and glossy finish that gives the product a premium look.

Metal: Metal cases offer durability and a luxurious appearance. These are often chosen for higher-end or specialty pressed powder cases.

Shape and Size

Pressed powder cases come in a variety of shapes and sizes, depending on the needs of the product. Standard shapes such as round or square are common, but custom shapes can be designed to make the packaging unique. Customizing the shape of the case not only creates a distinctive appearance but can also improve functionality, such as ease of use or portability.

Color and Finish

The color and finish of the pressed powder case can be customized to match the branding and aesthetics of the product. Suppliers offer a variety of options, including matte, glossy, and metallic finishes. These options can create a sleek and modern look or a more elegant and sophisticated feel, depending on the brand's image.

Colors can also be customized to align with brand identity, making it easier to create a cohesive packaging design across different products in a cosmetic line. Whether it’s soft pastels for a beauty brand or bold, vibrant colors for a younger audience, the color choices help to convey the brand message effectively.

Branding and Artwork

Custom branding and artwork are essential for any pressed powder case. Whether through logos, slogans, or intricate patterns, branding makes the packaging unique and recognizable. Various printing techniques such as silkscreen printing, UV printing, and embossing are available to imprint the design onto the case.

Silkscreen Printing: Common for logos and simple designs, this method ensures durability and clarity.

UV Printing: Allows for intricate designs and vibrant colors, making it ideal for more detailed artwork.

Embossing/Debossing: These techniques create a textured logo or design, adding a tactile element to the packaging.

Functional Features

In addition to aesthetic customization, functional features can also be added to pressed powder cases. Some of the common features include:

Mirrors: Built-in mirrors inside the case offer convenience, allowing users to apply powder on the go.

Sponge Holders: A dedicated space for sponges or puff applicators helps keep them hygienic and easy to access.

Locking Mechanisms: A secure locking system ensures that the case remains closed during travel, preventing spills or accidents.

Customization options for pressed powder cases are abundant, offering brands the opportunity to create packaging that meets both functional and aesthetic needs. From choosing materials and finishes to incorporating branding, artwork, and practical features, pressed powder cases can be tailored to reflect the identity of the product and improve the consumer experience. By investing in customized pressed powder cases, brands can stand out in a competitive market while ensuring their products are both attractive and practical for their customers.

English

English  中文简体

中文简体  عربى

عربى  Español

Español